Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Alkaline battery & Button cell manufacturing process-News

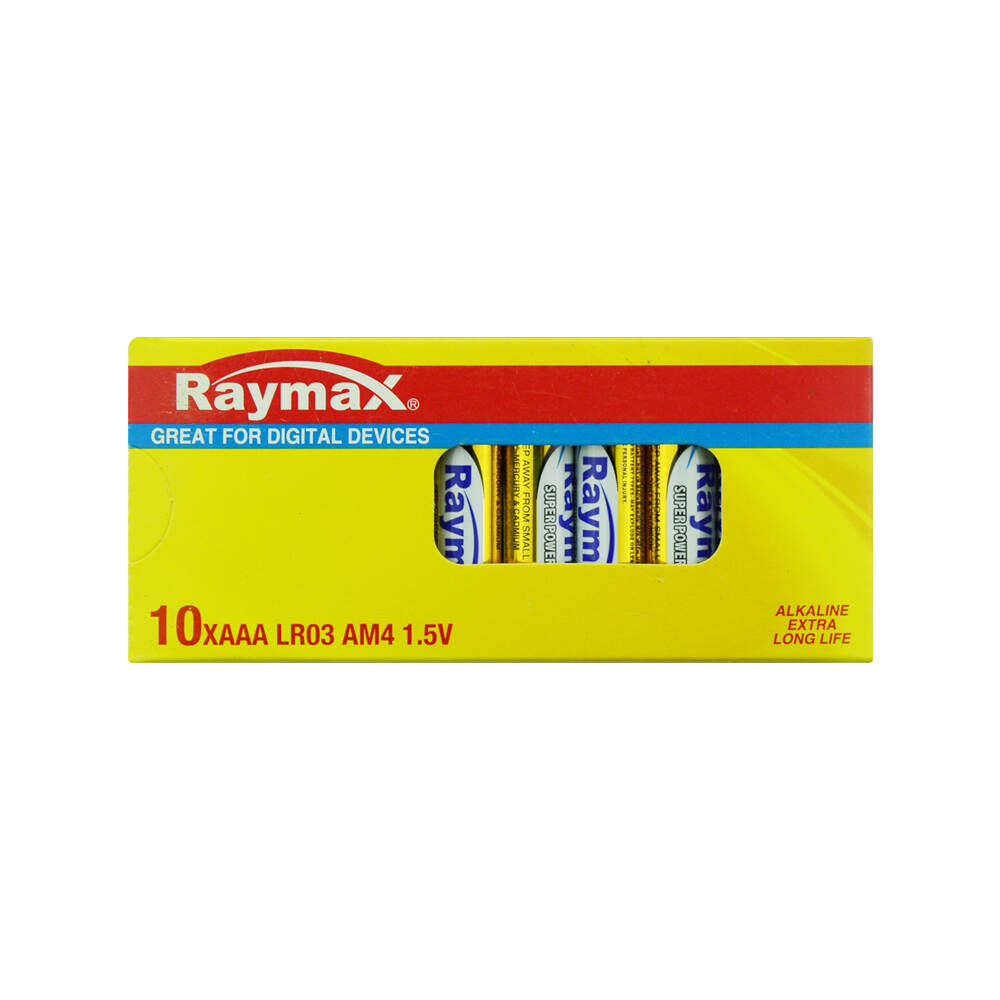

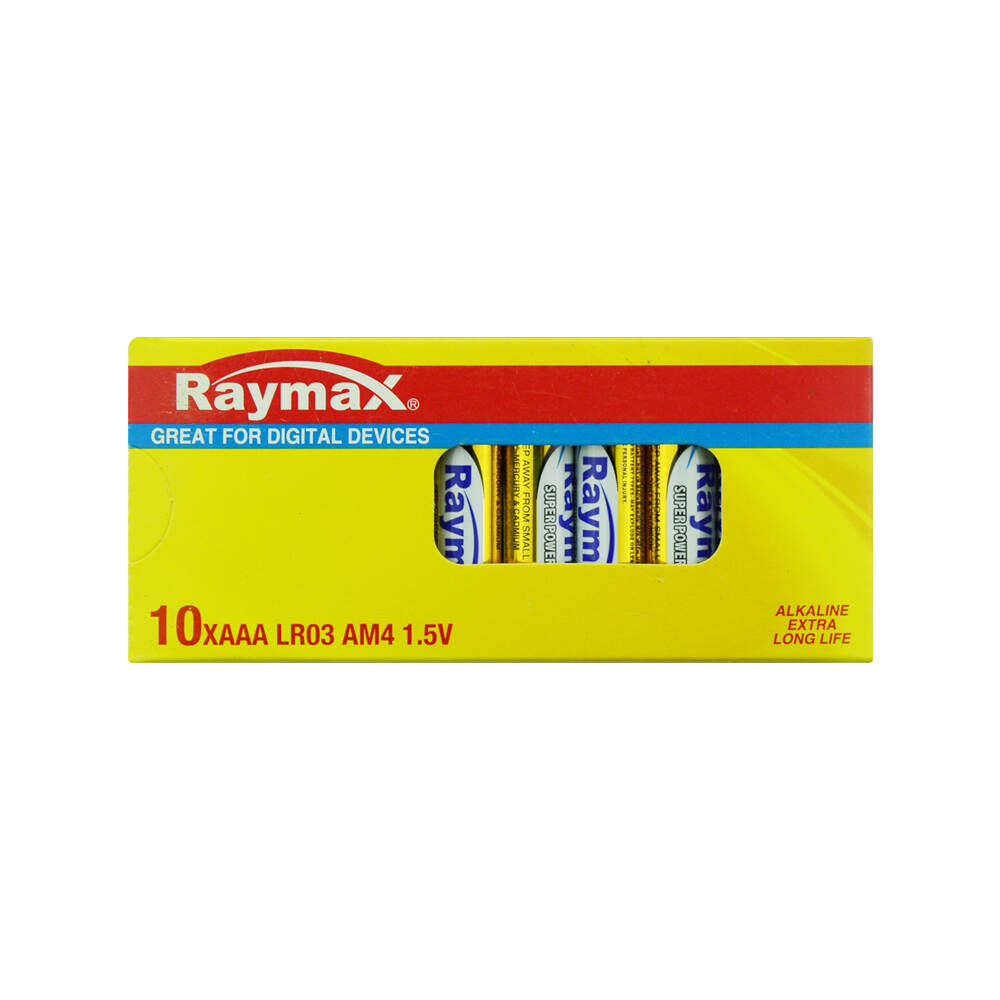

Introduction to OEM Mini AAA Batteries and Their Manufacturing Process

In today's digital age, electronic devices are ubiquitous. The role of batteries cannot be overstated, especially regarding mini AAA batteries. These small yet powerful energy sources play crucial roles. They power various electronic gadgets, from remote controls to small handheld devices. This article explores OEM mini AAA batteries. It examines their significance in electronics. Insights into manufacturing processes will be provided. Quality assurance measures will also be discussed.

What are OEM Mini AAA Batteries?

Definition and Basic Specifications

OEM mini AAA batteries are compact cylindrical cells. They commonly provide power in small electronic devices. Their typical measurements are 10.5mm diameter and 44.5mm length. This makes them smaller than AA counterparts. Despite size differences, their performance remains equally essential. These batteries usually operate at 1.5 volts. Capacities vary depending on applications. Manufacturer specifications also influence capacity variations.

Significance in Various Electronic Devices

Mini AAA batteries have wide usage. They serve everyday electronics extensively. Examples include TV remote controls. Digital cameras use them frequently. Handheld gaming consoles rely on them. Small flashlights often employ these batteries. Their versatility enables broad compatibility. They work with multiple brands. Numerous device types accept them. Compact size enhances their appeal. Reliable performance makes them preferred choices. Manufacturers prioritize efficient power solutions.

Manufacturing Process and Quality Assurance

Manufacturing Process Overview

Producing OEM mini AAA batteries involves intricate steps. Performance and safety must both be ensured. The process starts with raw material selection. Preparation follows material selection. Common materials include zinc for anodes. Manganese dioxide serves cathodes. Potassium hydroxide acts as electrolyte. These undergo stringent quality checks. Industry standards must be met. Only approved materials proceed to assembly.

Materials Used in OEM Mini AAA Batteries

Material quality directly impacts performance. Durability depends on component grades. High-grade zinc ensures optimal energy output. Manganese dioxide guarantees longevity. Consistent power delivery requires quality materials. The electrolyte facilitates electrochemical reactions. Its formulation requires careful attention. Enhanced conductivity is crucial. Efficiency improvements depend on electrolyte composition.

Production Steps

The manufacturing process employs precise engineering. Reliable performance demands meticulous assembly. Key production stages include:

- Material Preparation: Raw materials undergo mixing. Processing creates battery components.

- Cell Formation: Layers get compressed strategically. Anode/cathode materials form cells. Porous membranes prevent internal shorts.

- Assembly: Terminals get attached. Battery cells receive sealing. Leakage prevention ensures safety.

- Electrolyte Injection: Measured quantities enter cells. Chemical reactions generate electricity.

Quality Control Measures

Quality assurance remains paramount throughout production. Rigorous checks occur at every stage. Defects get identified promptly. Performance consistency gets enforced. Key quality steps include:

- Capacity Testing: Verifies energy delivery capabilities. Lifespan specifications get confirmed.

- Voltage Testing: Measures output under loads. Required specifications must be satisfied.

- Leakage Testing: Ensures seal integrity. User safety gets prioritized.

Environmental and Safety Standards

Compliance governs manufacturing practices. ISO standards get strictly followed. RoHS regulations restrict hazardous substances. Mercury gets eliminated from production. Cadmium usage gets prohibited. Environmentally sustainable methods get implemented.

Packaging and Distribution

Approved batteries enter packaging phases. Protective designs prevent transport damage. Industry safety standards guide packaging choices. Plastic seals prevent moisture exposure. Short circuit risks get minimized. Labels display specifications clearly. Safety instructions get printed visibly. Disposal guidelines accompany products.

Distribution networks span globally. Retailers receive shipments regularly. Electronics manufacturers get bulk deliveries. Commercial buyers obtain large packages. Consumers purchase smaller packs. Market demands determine packaging formats.

Advancements in OEM Mini AAA Battery Technology

Technological evolution drives battery improvements. Higher capacity demands get addressed. Extended lifespan becomes achievable. Safety features undergo enhancements. Electrolyte formulations get optimized. Anode/cathode materials see upgrades. Manufacturing techniques improve efficiency.

Environmental solutions gain momentum. Rechargeable versions reduce waste. NiMH batteries grow popular. Lithium-ion alternatives emerge. Frequent replacements get minimized. Cost savings attract consumers.

Challenges in the OEM Mini AAA Battery Industry

Performance-environment balance poses difficulties. Climate concerns pressure manufacturers. Harmful material reduction becomes imperative. Recyclability requirements intensify. Energy-efficient processes get prioritized.

Device demands strain innovation capabilities. Energy density expectations rise. Compact designs must retain power. Safety standards cannot be compromised.

Applications of OEM Mini AAA Batteries in Modern Life

The versatility of mini AAA batteries extends across industries. Medical devices utilize their compact power. Hearing aids rely on their steady output. Wearable fitness trackers depend on their efficiency. Smart home sensors employ them discreetly. Portable audio devices draw energy from them.

Their role in emergency equipment is critical. Smoke detectors use them for constant vigilance. Emergency flashlights store them for outages. Security systems integrate them for backup. Reliability defines their value proposition.

Future Trends in Mini AAA Battery Development

Research focuses on energy density improvements. Scientists explore nanotechnology applications. Graphene integration shows potential. Solid-state designs gain traction. These innovations aim to boost capacity.

Sustainability remains a core focus. Biodegradable materials undergo testing. Recycling programs expand globally. Closed-loop systems get prioritized. Eco-conscious manufacturing reduces carbon footprints.

Consumer Tips for Maximizing Battery Life

Proper storage extends battery longevity. Cool, dry environments are ideal. Avoid extreme temperature exposure. Remove batteries from unused devices. Prevent leakage risks proactively.

Smart usage habits enhance performance. Match battery types to device needs. Rechargeables suit high-drain gadgets. Dispose of spent batteries responsibly. Recycling centers accept them freely.

Sustainability Efforts in Battery Production

Manufacturers adopt green chemistry principles. Toxic material substitution accelerates. Water-based electrolytes replace harmful solvents. Renewable energy powers production lines. Carbon-neutral goals drive innovation.

Collaboration with recyclers strengthens circular economies. Battery components get recovered systematically. Zinc and manganese undergo repurposing. Landfill waste reduction becomes achievable.

Global Market Dynamics for Mini AAA Batteries

Emerging economies drive demand growth. Affordable electronics proliferate rapidly. Urbanization boosts device ownership. E-commerce platforms facilitate accessibility. Competitive pricing pressures manufacturers.

Regulatory landscapes shape industry practices. Stricter safety laws get enforced. Cross-border trade agreements influence supply chains. Tariff adjustments impact pricing strategies.

Innovations in Battery Recycling Technologies

Automated sorting systems improve efficiency. AI identifies battery chemistries accurately. Hydrometallurgical processes extract metals safely. Black mass conversion gains scalability. Valuable materials re-enter production cycles.

Public awareness campaigns educate consumers. School programs teach disposal ethics. Retail drop-off points multiply. Corporate take-back initiatives gain momentum.

Conclusion

OEM mini AAA batteries power modern electronics indispensably. Remote controls depend on them. Portable gadgets utilize their efficiency. Manufacturing reveals sophisticated technology. Quality controls ensure reliability. Environmental considerations shape production.

Consumer expectations continue evolving. Powerful solutions get demanded. Eco-friendly alternatives gain traction. Manufacturers face evolving challenges. Global market needs require adaptability. Safety regulations remain non-negotiable. Industry advancements will persist. Electronics innovation depends on battery progress.